Silo staves are the building blocks that form the walls of many traditional silos. Just as bricks are essential to a house, silo staves are vital to building a sturdy, reliable silo structure.

Their role is critical: they give silos the strength to withstand pressure, weather, and time, all while keeping stored materials safe and dry. In other words, the resilience, longevity, and functionality of a silo all depend on its staves—making them an irreplaceable part of silo construction.

Built to Last: Silo Staves Over the Years

Initially, most old silos were built as wooden structures, using wood staves that were bound together with steel hoops—much like a barrel. Redwood, known for its durability and resistance to decay, was a popular choice for a time. However, wooden silos had a major drawback: they didn’t last as long, often needing replacement due to wear and weather damage. This prompted a need for better, more lasting alternatives.

Concrete stave silos – so named because of their use of concrete staves quickly became the standard in silo construction. These silos, made from sturdy, flat concrete blocks, were a big improvement over wood. Not only did they last longer, but they also offered better insulation, keeping the contents at a more stable temperature. Concrete stave silos proved to be a more practical and lasting choice for many farmers and industrial users.

Types of Silo Staves: A Closer Look

Depending on the type of silo and its purpose, staves can be made from different materials.

Here’s a closer look at the main types:

- Concrete Stave Silos: Known for their strength and long lifespan, concrete staves are a popular choice, especially on dairy farms and other operations where durability is key. Reinforced with steel hoops (metal bands that wrap around the silo to hold everything tightly in place), these staves are commonly used to store silage, corn, and other feed.

- Wood Silos and Redwood Staves: Many farms still use these, especially smaller or older silos. Redwood staves are durable and have a natural resistance to pests, but they’re not as common as concrete staves today. Still, for those who appreciate the classic look and function, wooden staves get the job done for an older silo.

- Concrete Blocks and Cement Stave Silo: Another variation uses concrete blocks or cement staves. These also use metal bands to keep them secure, making them strong and stable. This style is especially common in industrial setups or on larger farms.

Each material has its own strengths, but all serve the same purpose: to create a strong, durable structure for storing feed, grain, and other important materials.

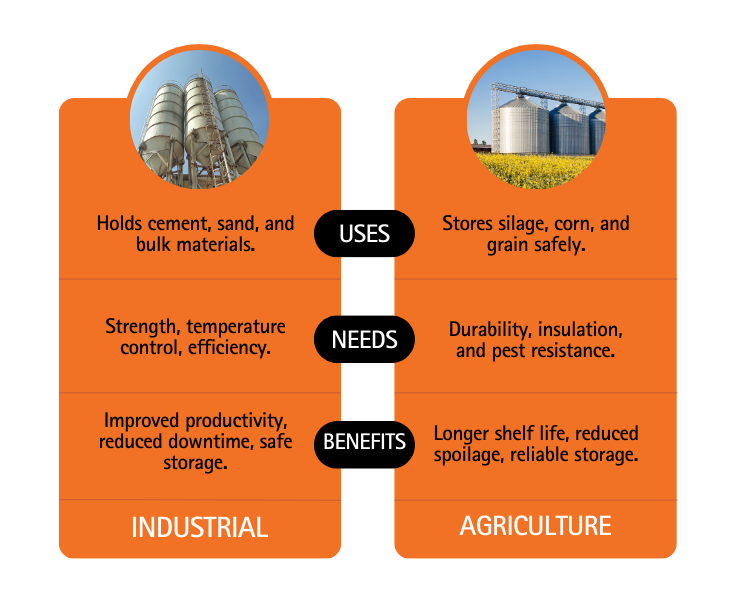

Importance of Silo Staves in Agriculture and Industrial Settings

Why are silo staves so important? Let’s start with farming. Farmers rely on silos to store materials like corn silage and livestock feed. Having a solid structure means you can count on your stored materials to be safe from the elements and pests. Whether you’re storing silage, corn, or grains, a well-built silo made from quality staves keeps things fresh and dry.

In industrial settings, like cement plants and ready mix companies, silos serve a different purpose. Here, they’re used to store bulk materials like cement, where strength is crucial to handle the heavy loads inside. With the right staves, these silos can support materials safely and efficiently.

Installation Process

Building a silo is no small task. The construction process starts with a building crew that stacks staves one by one.

A skid-steer loader is typically used to lift and position each stave, making the work both safer and more efficient. Once all the staves are in place, they’re firmly held by metal hoops or steel bands that wrap around the outside of the silo, reinforcing its structure and holding them all together.

Safety is a top priority throughout the process. Working at heights and handling heavy materials requires certified crews trained in safe practices. Every step is carefully planned to make sure the silo stays solid and reliable, whether it’s being built for the first time or undergoing repairs.

Maintenance and Repairs for Silo Staves

Over time, even the toughest silos need a little TLC. Regular maintenance is key to keeping your silo in good shape, and catching small issues before they turn into big, costly problems.

Common issues that affect silos include:

- Cracking

- Water damage

- Wear on metal hoops

- Rust on steel components

- Pest infestation (wooden silos)

- Loose silo cap

- Foundation shifting

For concrete silos and staves, concrete chipping might be needed to remove any buildup. Concrete chipping can also repair worn areas and prevent weakening of the silo’s structure. Wooden silos, on the other hand, may need occasional treatments for pests or wood rot, as these can compromise the integrity of the silo over time.

Don’t forget the importance of inspecting parts like the silo cap, bottom, and silo wall. These are all crucial to the structure’s overall health.

When repairs are necessary, it’s best to call in experts who have the right equipment and know-how to ensure the work is done safely and effectively. A little attention to maintenance can go a long way in preserving the silo’s strength, keeping it reliable for years to come.

The Value of Working with a Trusted Silo Company

When it comes to silos, having a trusted company by your side can make all the difference. Professional silo services don’t just help maintain silos—they help extend the lifespan of your investment, keeping your farm silo, barn, cement terminal, or plant running smoothly.

With over three decades of experience, Silo Pros is equipped to handle the unique needs of silos across various industries.

Here’s how Silo Pros supports clients in maintaining and maximizing their silo systems:

- Concrete Chipping: For concrete staves, removing built-up residue or worn concrete can be a challenge. We provide concrete chipping services, carefully removing stubborn buildup without damaging the structure. This process not only clears space within the silo but also maintains the interior surface that’s essential for safe storage.

- Silo Repairs: Over time, structural damage can compromise a silo’s stability. At Silo Pros, we provide repair services, addressing everything from minor cracks to more extensive structural concerns.

- Silo Cleaning: Our team uses advanced cleaning techniques to remove hardened buildup, ensuring silos maintain their full capacity and operate without interruptions. Regular cleaning also helps prevent contamination, keeps materials in good condition, and reduces wear on the silo structure.

- Silo Maintenance: Routine maintenance helps detect signs of wear or damage before they become costly problems. By keeping your silo in top shape, Silo Pros helps reduce downtime, improve safety, and maintain efficient storage conditions.

With expertise in silo repairs, cleaning, maintenance, and concrete chipping, our team brings the experience, tools, and dedication needed to keep your silo operating at its best. Our company’s crews are OSHA and MSHA-certified, proving their competence in confined space entry, working at heights, and lift operations.

Protect Your Investment

Whether you’re dealing with an older silo or maintaining a modern one, Silo Pros’ reliable services ensure your silo meets your storage needs for years to come.