Asphalt Silo and Central Drum Mixer Cleaning

SERVICES THAT TACKLE THE TOUGHEST BUILDUP

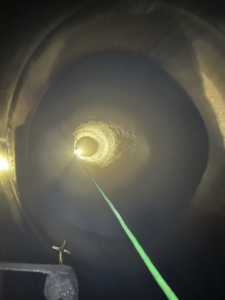

When hot mix asphalt starts sticking to side liners, batcher gates, and drag conveyors, it’s time for a deep clean. Silo Pros provides Asphalt Silo Cleaning and Central Drum Mixer Cleaning services that tackle the toughest buildup in silo systems. Whether you’re dealing with a ton silo or a drag slat conveyor, we have the tools and experience to clean it right.

WHY CLEAN YOUR ASPHALT PLANT?

Hot summers and high ton capacities mean silos, drag slats, and mixers take a beating. Over time, asphalt storage areas build up hard layers of material that reduce capacity and strain your equipment. This accumulation can cause major wear, slowdowns, and even safety issues, especially in critical parts like main drag conveyors, clamshell gates, and truck scales. Regular cleaning maximizes efficiency, reduces breakdowns, and keeps you in compliance with occupational safety standards, protecting both your equipment and your bottom line.

Clean equipment doesn’t just look better—it operates better.

OUR ASPHALT REMOVAL SERVICES

Silo Pros provides the most effective cleaning solutions for asphalt plants, including vacuum truck services and high-pressure water blasting. Whether it’s routine maintenance or a tough build-up removal, we’ve got your asphalt plant components covered.

ASK THE PROS

ADDITIONAL INDUSTRIAL SERVICES

GET YOUR ASPHALT PLANT

RUNNING LIKE NEW

ONE CALL CLEANS IT ALL

Silo Pros, Inc

915 Doyle Rd, #303-128

Deltona, FL 32725

PH: 813-546-6323 • EM: keith@siloprosusa.com