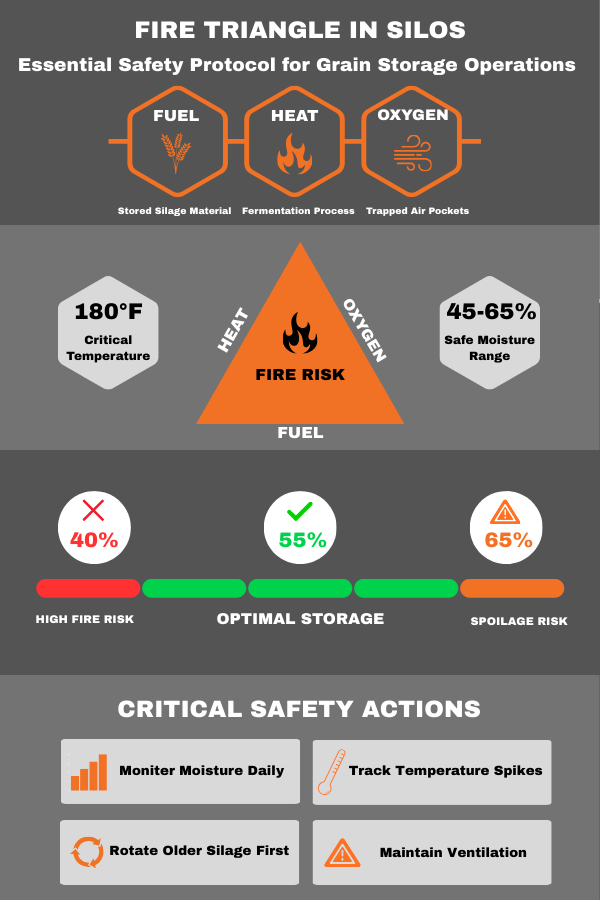

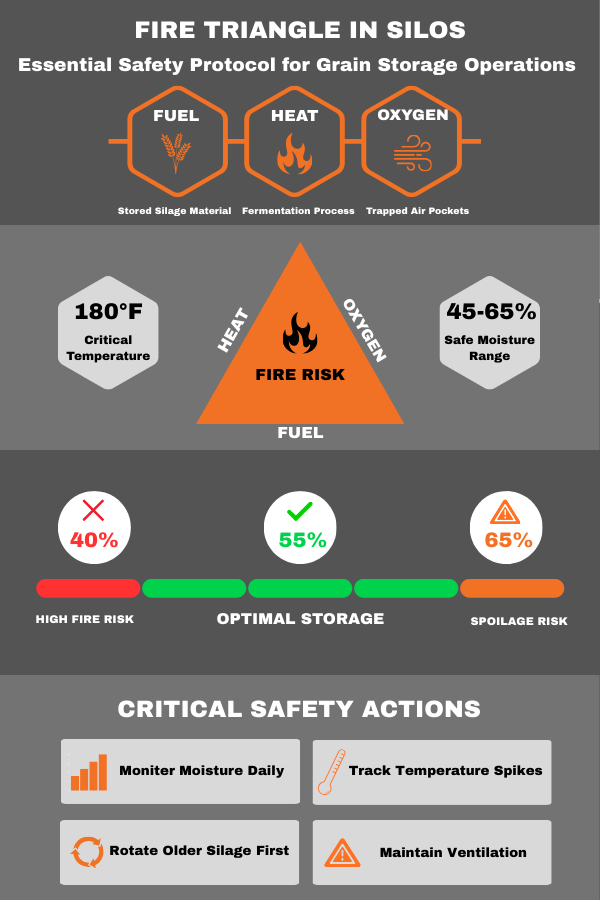

The Short Answer: Silo fires and spontaneous combustion typically occur when dry silage combines with oxygen during fermentation, creating dangerous hot spots. Prevention relies on maintaining proper moisture levels (45-65%) and keeping oxygen-limiting silo structures sealed against air infiltration.

A silo fire can destroy stored materials and cause catastrophic structural damage to storage infrastructure. These dangerous incidents stem from three basic elements combining at the wrong time: heat generated during fermentation, unwanted oxygen infiltration, and the stored silage itself serving as fuel. When a silo burns, the consequences extend beyond material loss – farms face lengthy downtime and expensive reconstruction costs.

To ensure optimal safety, guidelines from industry leaders such as the Occupational Safety and Health Administration (OSHA) suggest a proactive approach to moisture control, ventilation, and temperature monitoring in silo management.

As highlighted by NIOSH, maintaining proper oxygen levels within silos is important for preventing hazardous conditions that can lead to combustion, particularly when moisture content falls below recommended levels.

Three elements combine to create a fire in an oxygen-limiting silo:

As highlighted by NIOSH, maintaining proper oxygen levels within silos is important for preventing hazardous conditions that can lead to combustion, particularly when moisture content falls below recommended levels.

Three elements combine to create a fire in an oxygen-limiting silo:

Understanding Silo Fire Risks

Silo fires typically start when dry silage material (below 40% moisture) combines with trapped air during the fermentation process, creating dangerous hot spots. The risk of a silo explosion increases when silos have poor maintenance, improper moisture levels, or ventilation issues that allow excess air to feed potential spontaneous combustion. Farms with older storage systems may have a particularly difficult time managing these risks without proper upgrades. Understanding the causes of silo fires provides the foundation for effective safeguard procedures. These incidents develop when specific conditions align, creating an environment where combustion becomes possible.The Fire Triangle in Silos

As highlighted by NIOSH, maintaining proper oxygen levels within silos is important for preventing hazardous conditions that can lead to combustion, particularly when moisture content falls below recommended levels.

Three elements combine to create a fire in an oxygen-limiting silo:

As highlighted by NIOSH, maintaining proper oxygen levels within silos is important for preventing hazardous conditions that can lead to combustion, particularly when moisture content falls below recommended levels.

Three elements combine to create a fire in an oxygen-limiting silo:

- The fuel: Stored silage material

- Heat: Generated during fermentation

- Oxygen: Trapped air in the silage

How Fermentation Creates Fire Risks

The fermentation process naturally generates heat – this is expected. However, when material becomes too dry, heat retention increases. As temperatures climb toward 180°F or higher, the risk of flame development and explosion rises significantly. Old silage that has been stored beyond recommended timeframes presents elevated fire risks due to continued breakdown processes.Moisture Content: A Critical Safety Factor

The USDA recommends maintaining silage moisture levels between 45-65%, as this range prevents both microbial spoilage and spontaneous combustion, ensuring the material remains safe for long-term storage.- Optimal range: 45-65% moisture

- Risk zone: Below 40% moisture

- Upper limit (above 65%): Creates spoilage risk, but reduces fire danger

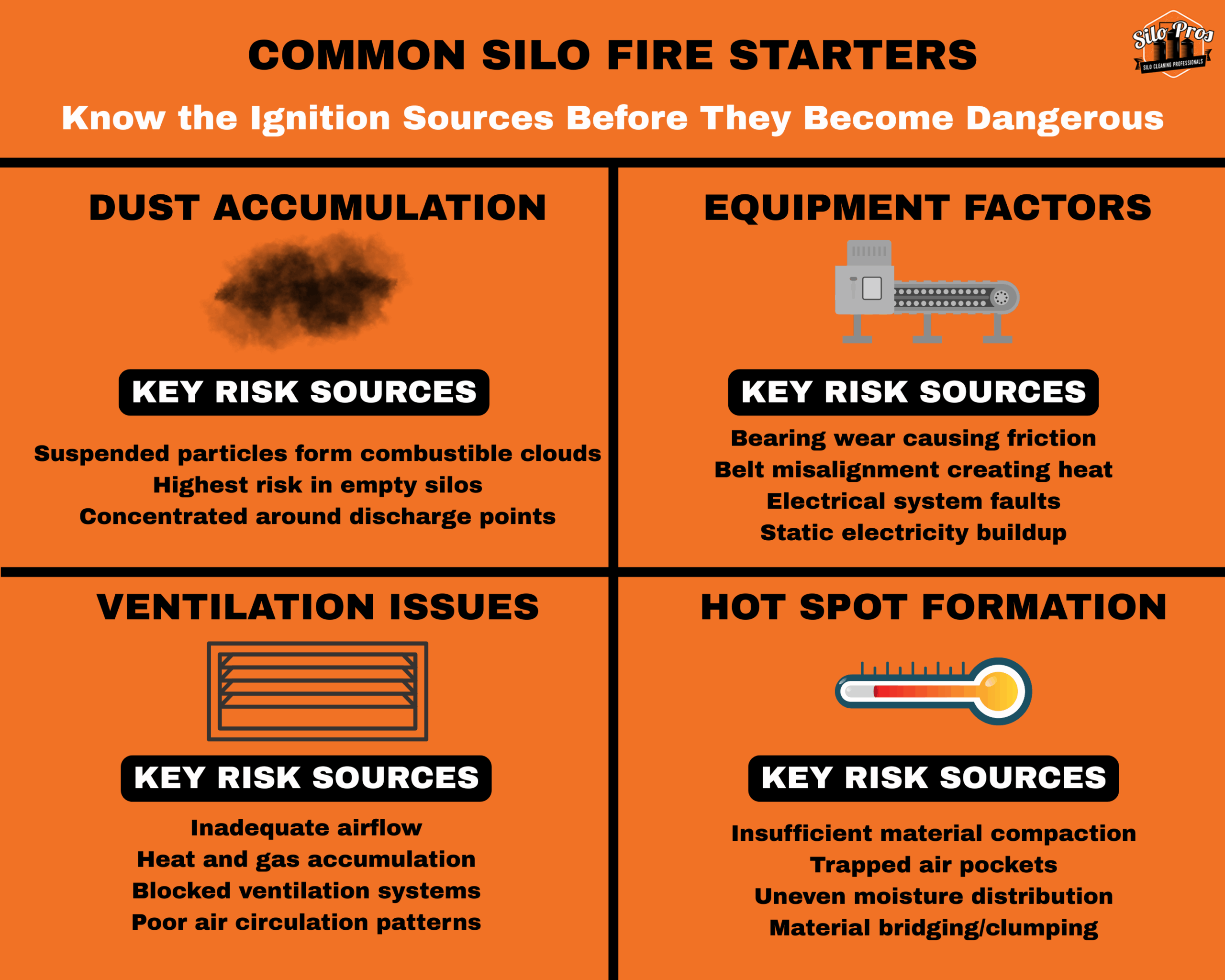

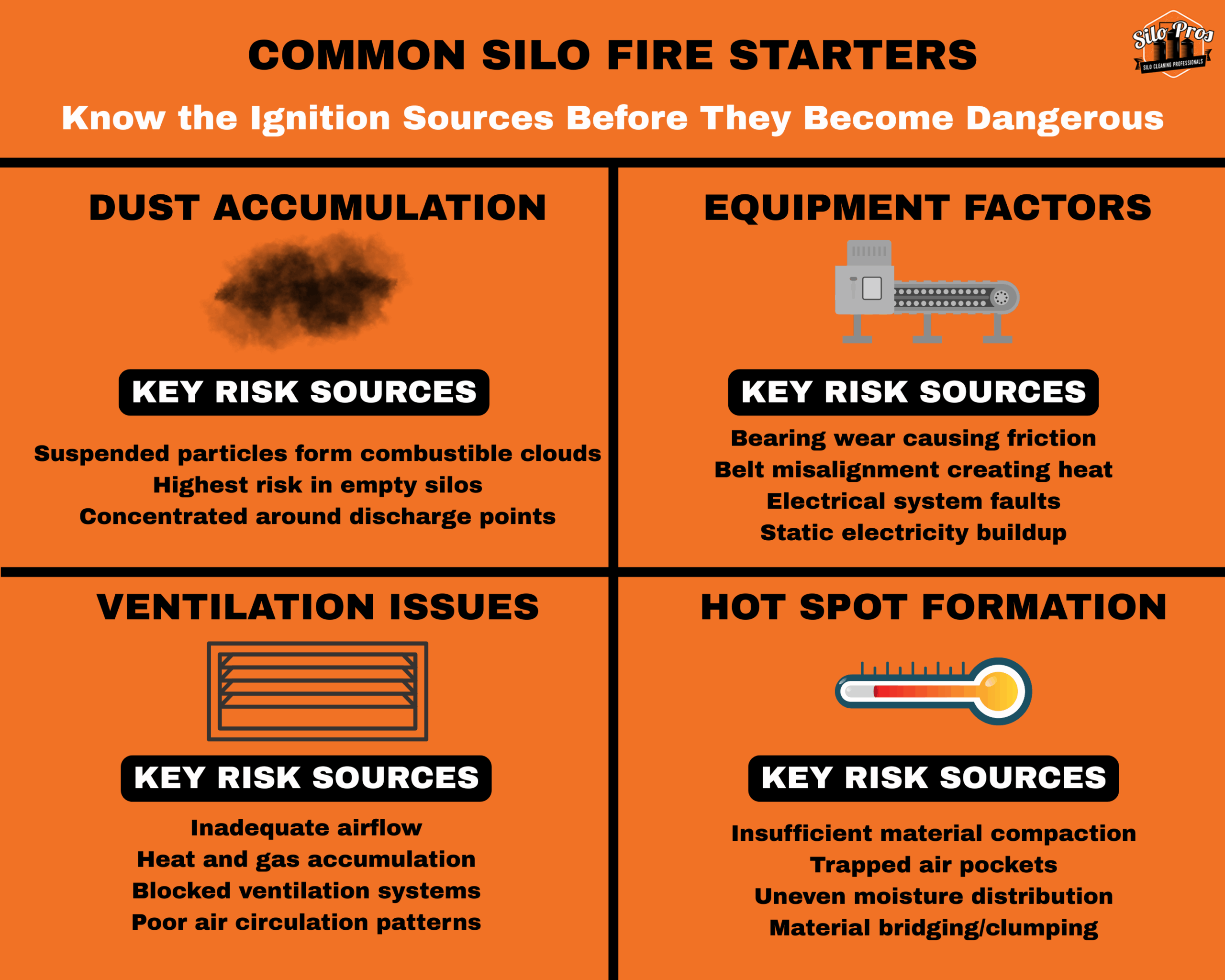

Common Fire Starters

Dust Accumulation

Suspended particles can form combustible clouds within the silo structure, leading to dust explosion risks. These clouds become highly dangerous when exposed to ignition sources, particularly in an empty silo where air circulation patterns can concentrate dust particles.Equipment Factors

- Bearing wear causing friction

- Belt misalignment

- Electrical system faults

- Static electricity buildup

Ventilation Issues

Inadequate airflow leads to heat and gas accumulation. Combined with trapped moisture, these conditions can trigger hot spots. An active system for monitoring ventilation performance helps identify problems before they escalate.Hot Spot Formation

Research from the Fire Protection Research Foundation shows that inadequate ventilation and poor airflow within silos are major contributors to the formation of hot spots that can lead to fires. Problem areas develop where:- Material compaction is insufficient

- Air becomes trapped

- Moisture distribution is uneven

- Material forms bridges or clumps