A silo dust explosion occurs when fine dust particles in a grain silo ignite, leading to a rapid and often devastating release of energy. These incidents can cause severe structural damage, injuries, and even fatalities, making it crucial to understand what causes them and how to prevent them.

For those managing grain silos or grain elevators, knowing the causes and taking the right precautions is key to keeping workers safe and protecting your investment.

What Causes Silo Dust Explosions?

A dust explosion occurs when fine dust particles become suspended in the air, creating a dust cloud that, under certain conditions, can ignite and cause a powerful explosion. In a grain silo, for example, fine grain dust can accumulate, and when mixed with air, it becomes highly flammable. All it takes is a potential ignition source, such as a spark from static electricity or a piece of faulty process equipment, to ignite the dust.

Primary vs. Secondary Dust Explosion

Dust explosions are often divided into two types: primary explosions and secondary explosions.

- Primary Dust Explosion: This happens when the initial ignition ignites the dust particles in a confined space like a silo or dust collector. While it may not be the largest blast, it can cause significant damage and disperse dust.

- Secondary Dust Explosions: When a primary explosion stirs up more dust, it can cause a larger secondary explosion. This is often the more destructive blast, as the dust cloud from the initial explosion mixes with airborne dust, creating a powerful explosion.

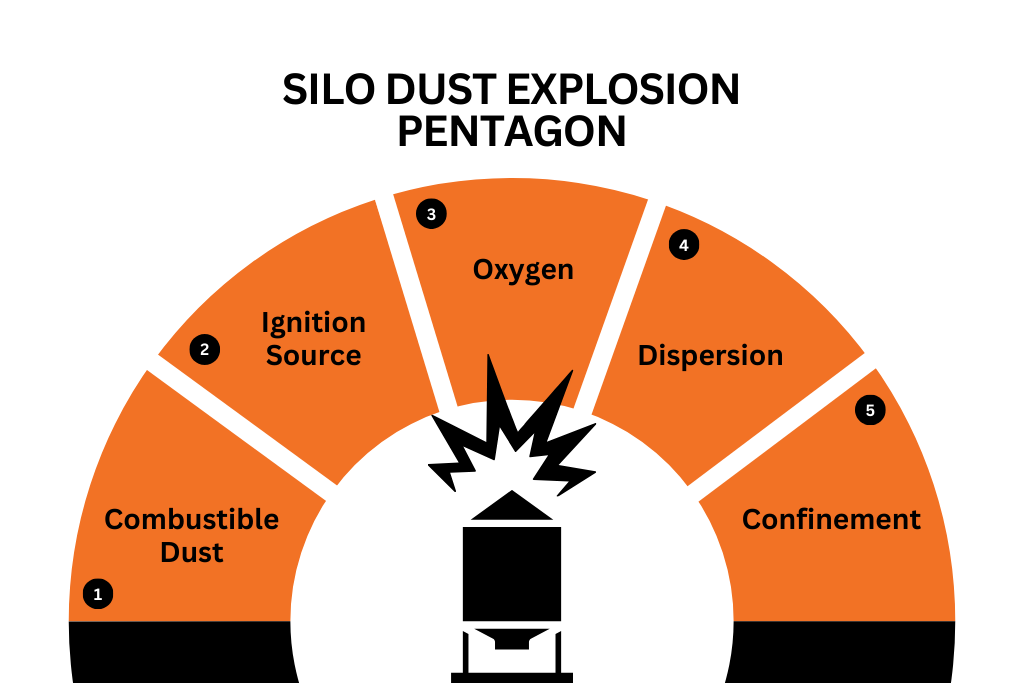

The Dust Explosion Pentagon

To understand how dust explosions happen, it’s helpful to look at the dust explosion pentagon, which outlines the five elements required for a grain dust explosion:

- Combustible Dust: Fine particles, like grain dust, flour dust, and coal dust, are all examples of combustible dust that can fuel an explosion. When dust builds up inside a silo, it creates a perfect environment for a potential blast.

- Ignition Source: A small spark from static electricity, machinery, or friction from process equipment like bucket elevators and rotary valves can ignite the dispersed dust, setting off a primary explosion.

- Oxygen: Like any fire, dust explosions need oxygen to ignite. The air inside a silo provides this essential ingredient.

- Dispersion: Dust needs to be dispersed into the air to ignite. For instance, activities like loading and unloading grain can stir up dust into a dust cloud.

- Confinement: The confined space of a grain silo traps the pressure, which can make an explosion more powerful.

When all these elements are present, a resulting explosion can occur, potentially causing significant structural damage.

Understanding the Impact of Silo Dust Explosions

A dust explosion in a grain silo can have devastating consequences, both for the facility and the people working there:

- Structural Damage: The force of an explosion can cause severe damage to the structure of a grain silo, potentially collapsing walls and roofs. This type of structural damage can require extensive and costly repairs.

- Health Risks: Dust explosions can release harmful gases like carbon monoxide, posing a health risk to workers. Exposure to high levels of these gases can be life-threatening.

- Impact on Insurance: Insurance companies often require strict compliance with safety measures to provide coverage. A dust explosion can lead to increased premiums or even loss of coverage if safety standards aren’t met.

- Industry Impact: Explosions aren’t just a risk for grain facilities—they also affect chemical plants, rice mills, and sugar dust facilities, making dust management and explosion prevention critical across multiple industries.

Understanding the full scope of these consequences underscores why prevention strategies are so important for the safety of team members, equipment, and silos.

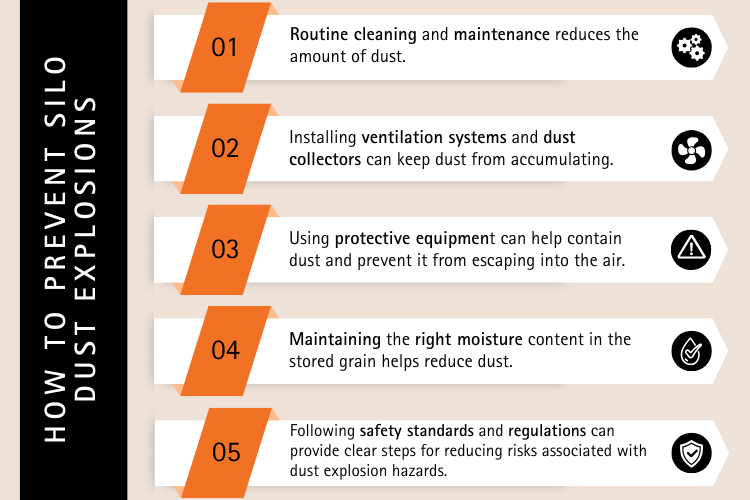

How to Prevent Silo Dust Explosions

Preventing silo dust explosions starts with proper maintenance and safety measures.

Here are some key strategies:

- Regular Silo Cleaning and Maintenance: Dust build-up inside silos is a major risk. Routine cleaning reduces the amount of fugitive dust and grain dust, preventing conditions that can lead to a grain dust explosion.

- Ventilation Systems and Dust Collectors: Installing efficient ventilation systems helps keep dust from accumulating. Dust collectors trap airborne dust, keeping the environment safer for workers.

- Protected Equipment: Using protected equipment like dust-tight rotary valves and well-maintained bucket elevators can help contain dust and prevent it from escaping into the air.

- Moisture Content Management: Maintaining the right moisture content in the stored grain helps reduce dust. Drier grains produce more dust, increasing the risk of explosions.

- Following Safety Standards: Adhering to safety guidelines from organizations like the National Fire Protection Association (NFPA) and health administration regulations can provide clear steps for reducing risks associated with dust explosion hazards.

Safety Standards and Compliance

Adhering to safety standards and regulations is crucial for minimizing the risk of dust explosions. The National Fire Protection Association (NFPA) provides guidelines on handling combustible dust. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for maintaining safe working environments in industries that handle combustible dust hazards.

Insurance companies often require compliance with NFPA and OSHA guidelines to offer coverage, as dust explosion risks can lead to significant claims for damages. Facilities that implement proper safety measures not only protect their workers but also demonstrate due diligence to insurance companies, potentially reducing their premiums.

Prioritize Safety to Prevent Silo Dust Explosions

Managing the risk of dust explosions requires expert knowledge and regular maintenance. This is where Silo Pros comes in. Our team specializes in silo repairs, cleaning, maintenance, and inspections to help you keep your facilities safe and compliant.

Here’s how:

- Customized Maintenance Plans: We create tailored plans to address specific issues like combustible dust build-up, fugitive dust control, and ventilation systems optimization.

- Expert Inspections: Our detailed inspections identify potential ignition sources and dust explosion hazards, ensuring that your facility meets safety standards.

- Ongoing Support: We offer ongoing support to ensure your grain silo remains in peak condition, reducing the risk of primary and secondary explosions.

- Baghouse Maintenance: Proper maintenance of your baghouse dust collection system is crucial to prevent hazardous dust accumulation. Our team ensures that your baghouse operates efficiently and reduces the risk of dust-related incidents.

With our help, you can protect your investment, ensure the safety of your team, and maintain compliance with industry standards.

REDUCE THE RISK OF DANGEROUS GRAIN DUST EXPLOSIONS

By following these prevention strategies and choosing a trusted partner like Silo Pros, you can prevent the next dust explosion and keep your facility running safely.