If you’ve been working with silos for a while, you know they can be finicky. One day, they’re working fine, and the next, you’ve got material stuck, refusing to budge.

Unclogging silos isn’t just about getting things moving again—it’s about keeping your storage systems working smoothly and safely. The last thing you want is a clog slowing down your operation, whether it’s cement, grain, or some other bulk material.

Let’s talk about what causes these clogs and the best ways to clear them out without risking life and limb.

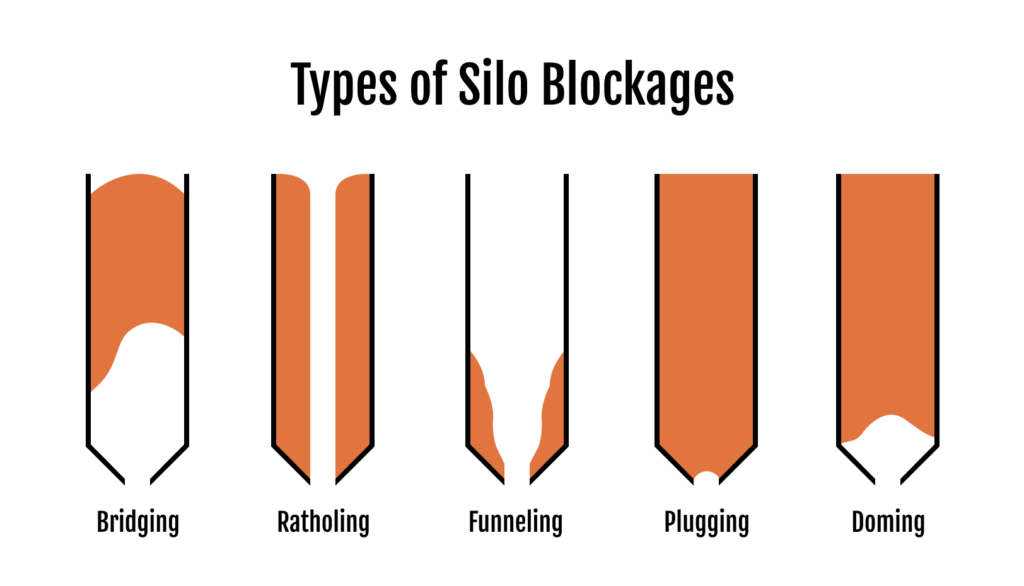

Common Types of Silo Blockages

Silos can develop all sorts of problems, mainly due to the behavior of the stored materials inside them.

Here are some of the most common types of blockages that can crop up in silos:

- Material Bridging: This is when built-up material forms a bridge over the opening, creating a solid arch that keeps everything else from flowing out. It’s stubborn and tough to break.

- Ratholing: Imagine a tunnel in the middle of your material, but the sides stay stuck. Material flows through the center, but the sides? Stuck tight against the silo wall.

- Compaction: When material sits for too long, especially in humid conditions, it can get compacted due to higher moisture content. Before you know it, you’ve got a solid block that won’t budge.

- Funneling: This happens when material flows only through a narrow path directly over the outlet, while the rest remains stuck against the walls. It can cause uneven flow, decrease storage capacity, and disrupt operations.

- Plugging: This occurs when the outlet becomes completely blocked, causing a complete halt in the flow. It can be especially tricky to clear out.

- Doming: A dome forms on top of the material inside the silo, creating a stable arch that blocks the flow beneath it. This type of blockage can be difficult to detect until material flow slows significantly.

And it’s not just one type of silo that faces this. Concrete silos, cement silos, steel silos—none of them are immune. Different materials like cement, grain, and coal all have their quirks. Each type of material brings its own challenges when it comes maintaining consistent flow and avoiding material buildup.

Effective Ways to Clear Silo Blockages

Now, let’s dig into the best ways to unclog those stubborn silo clogs. There are a few methods to get things flowing again, each with its own pros and cons. Here’s a closer look at each:

Air Lance

This method uses high-pressure air to blast through blockages. It’s ideal for loosening dry bulk materials like grain or dry cement. Air lances can target specific areas within the silo, making them effective for small, isolated clogs. However, they might struggle with more compacted material.

Acoustic Cleaner

Acoustic cleaners create sound waves that vibrate materials inside the silo, breaking up clogs without the need for human entry. They’re especially handy for dry, sticky materials that tend to cling to the silo walls. Acoustic cleaners are a non-invasive option, perfect for keeping material flowing before it has a chance to settle and harden. While not as powerful as other methods, they work well as a preventative measure.

Silo Whip

A bin whip is a mechanical tool that rotates and breaks apart even the toughest build-up. It’s powerful and can tackle stubborn clogs that other methods might struggle with. A bit more involved in setup, it’s well-suited for dealing with large, compacted areas that won’t budge with air or sound. While effective, using a bin whip requires careful handling to avoid damaging the interior walls and steel plates inside the silo.

Confined Space Entry

Sometimes, the only option is to send a trained professional inside the silo to manually clear the blockage. This method is riskier due to the need for human entry, but it’s highly effective when other tools can’t reach the problem. It’s best reserved for particularly severe or hard-to-reach blockages where precision is needed. Safety precautions are critical, making this method best handled by experts.

Air Cannon

Air cannons release a powerful burst of air inside the silo to break up compacted material or stubborn clogs. They’re effective for larger storage silos where clogs occur frequently. Air cannons can be positioned strategically around the silo to address flow issues quickly, making them a go-to choice for facilities that handle high volumes of material. They’re not as precise as some methods, but they get the job done fast.

Vibration Pads

Attached to the exterior of the silo, vibration pads create gentle vibrations that help dislodge materials stuck to the interior walls. They’re often used as a preventative tool, keeping materials moving smoothly before they have a chance to settle.

Hydro Cleaning

Hydro cleaning uses high-pressure water jets to cut through dense material build-up. This method works well for silos containing compacted, stubborn materials and is particularly effective in non-porous silos. Hydro cleaning can reach areas that other tools can’t, making it a strong choice when dealing with materials that have hardened over time. However, it’s not suitable for every type of material, so it’s best used where water won’t cause damage.

Vacuuming

Vacuuming is a less aggressive but precise method, using powerful vacuum systems to remove loose or semi-compacted materials. It’s ideal for situations where you want to preserve the integrity of the stored product or where more invasive methods might cause damage. Vacuuming is particularly effective in agricultural silos where delicate grains or seeds need to be removed without breakage.

When the Tough Jobs Call, Silo Pros Answers

For the most stubborn clogs, sometimes the best solution is hands-on. The Silo Pros team isn’t afraid to get inside the silo, tackling blockages directly. It’s a risky job, but it’s the best way to ensure a thorough clean.

Why You Should Consider Professional Silo Clog Removal

Handling silo clogs on your own might seem tempting, but there are big benefits to hiring a professional silo cleaning service. Professionals bring the right tools—like air cannons and siloo whips—to tackle tough clogs with less downtime. Their experience with different types of silos, from steel silos in energy plants to concrete silos in agriculture, means they understand how to address material build-up without causing damage. It’s a safer, faster way to get back to work without risking dents or delays.

Leave the Tough Jobs to Silo Pros

When it comes to keeping your silos in peak condition, Silo Pros is the partner you can trust. Our silo cleaning service is designed to handle even the toughest blockages, keeping your operation running smoothly.

Here’s what makes us the top choice for your silo maintenance:

- Comprehensive Cleaning Services: Our trained professionals can enter silos and concrete structures safely to tackle clogs that other methods can’t reach. With specialized techniques, we can break down even the most stubborn buildup, making sure your silos are free of obstructions.

- Commitment to Employee Safety: At Silo Pros, safety comes first. Our team is trained to meet the highest safety standards, whether working inside confined spaces or operating specialized equipment. We take every precaution to protect our team and yours, keeping employee safety as a top priority during every job.

- Expert Repair Services: Beyond cleaning, Silo Pros offers expert repair services for your silos. If we find any damage or wear during the cleaning process, our team can address it promptly, preventing small issues from becoming costly problems. This means you get more than just a cleaning—you get a proactive partner that looks out for your investment.

- Minimized Downtime: We know how important it is to maintain your production schedule. That’s why our services are designed to keep interruptions to a minimum. Our team works quickly to get your silos and storage vessels back in action, reducing delays that can impact your bottom line.

When you choose Silo Pros, you’re choosing a team that’s committed to doing the job right—prioritizing safety, dependability, and keeping your silos running strong for years to come.