A standard concrete truck can hold up to 10 cubic yards of concrete. This is the most common capacity for trucks delivering ready-mix concrete in the United States. However, there are variations in truck sizes to fit different job needs, ranging from small portable mixers to larger volumetric mixers.

Types of Concrete Trucks and Their Capacities

1. Standard Concrete Trucks

The majority of concrete trucks you’ll see on the road or at a construction site are standard mixer trucks. These trucks typically hold 8-10 cubic yards of concrete. They’re a great choice for larger projects, such as pouring a driveway, a foundation, or a concrete slab.

2. Volumetric Mixers

A volumetric mixer truck is designed to mix concrete on-site. Instead of carrying pre-mixed concrete, it holds the raw materials (like sand, Portland cement, and water) in separate compartments and mixes them as needed. This type of truck is perfect for smaller projects or jobs where you don’t know the exact amount of concrete you’ll need. With a volumetric truck, you can avoid paying an additional fee for a short load since you only use what’s required.

3. Smaller Trucks for Smaller Jobs

Not every project requires a full truckload. For smaller projects, like pouring a few fence posts or fixing a small concrete pad, you might use a portable concrete mixer or a mini-mix truck. These mixers hold up to 2 cubic yards and are easy to transport to tight spaces.

4. Larger Trucks for Larger Jobs

For large projects, like massive foundations or industrial concrete pours, some trucks can carry up to 12 cubic yards. However, these large trucks are less common due to road weight restrictions. Projects requiring more than 10 cubic yards typically involve multiple deliveries or the use of a concrete pump truck to spread the material efficiently.

Balancing Capacity and Weight Restrictions

When it comes to concrete trucks, size and capacity are only part of the equation. A single cubic yard of concrete weighs about 4,056 pounds, so you can imagine the strain this places on a mixer truck. To transport such heavy loads, trucks must be built to handle the weight, but they also need to comply with state weight regulations. These limitations can affect how much concrete a truck can legally carry, even if it’s designed to hold a full load. This is just one of many factors influencing a truck’s actual capacity on any given job.

Factors That Affect Concrete Truck Capacity

Concrete trucks don’t always carry their maximum load. Several factors influence how much a truck can actually deliver.

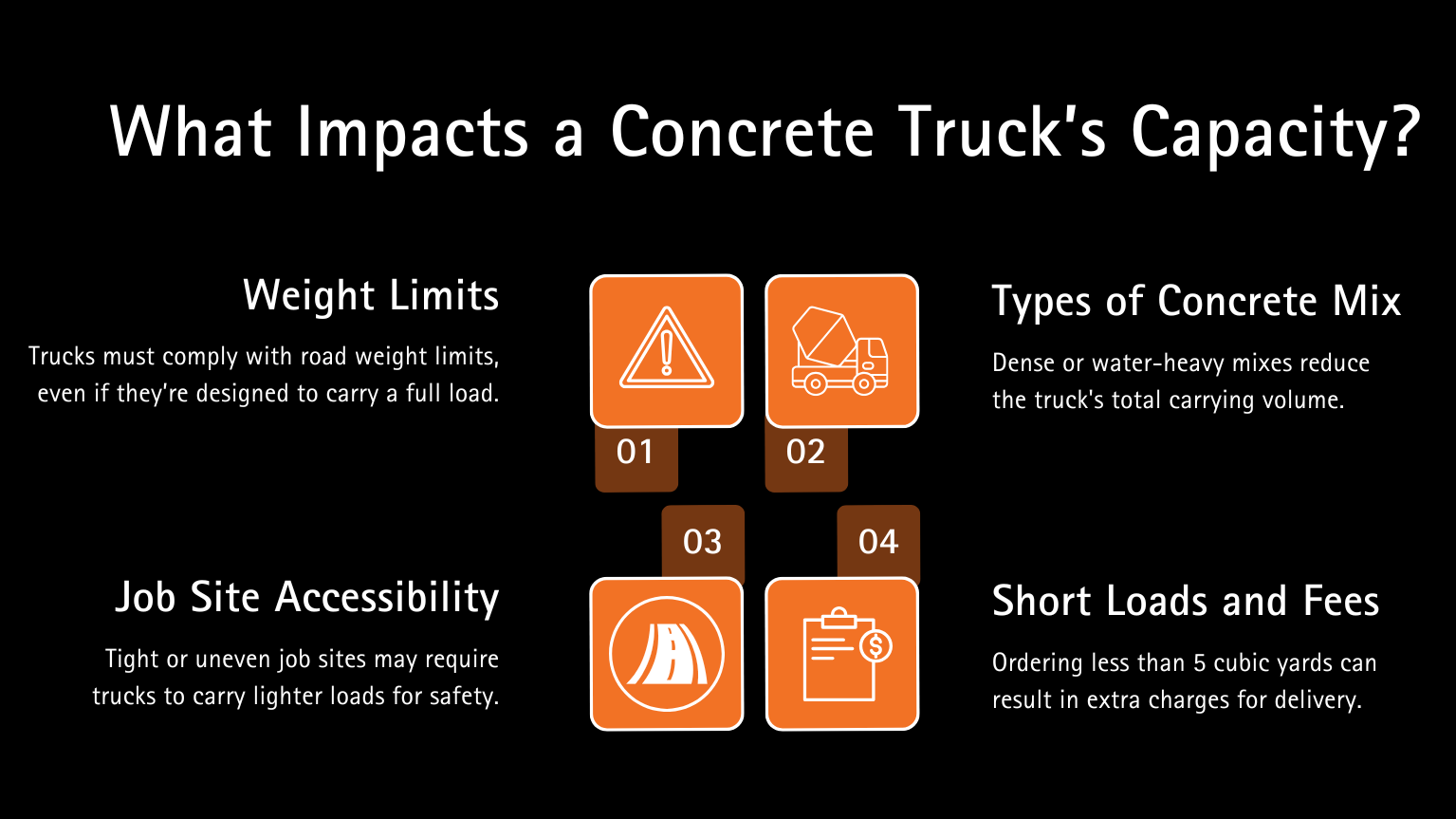

Weight Limits

As mentioned previously, every truck has a maximum weight limit, and so do the roads it travels on. Even if a truck can technically hold 10 cubic yards of concrete, it might not be able to carry that much if it exceeds local road weight restrictions. Concrete is heavy, so it’s important to keep this in mind when planning your delivery.

Type of Concrete Mix

The type of concrete mix used can also impact the capacity. Certain mixes are denser or require extra water, which reduces the total volume that can be carried.

Job Site Accessibility

The layout of the construction site can limit the amount of concrete a truck can deliver. If the site has narrow access points or uneven terrain, the truck may need to carry a lighter load for safety reasons. Trucks designed for rear discharge can help in tight spaces, but the driver still needs enough room to maneuver.

Short Loads and Fees

If you don’t need a full load, many suppliers will still charge you for the truck’s time and transport. This additional charge is common when ordering less than 5 cubic yards. Knowing exactly how much concrete you need avoids these extra costs.

Planning a Successful Concrete Delivery

- Use a Concrete Calculator: One of the easiest ways to figure out how much concrete you need is by using a concrete calculator. These tools help you estimate the amount of concrete based on the size of your project. For example, if you’re pouring a patio, you’ll need to calculate the square foot area and multiply by the depth to get the total volume in cubic feet, then convert to cubic yards.

- Coordinate with Your Supplier: Working with a reliable ready mix supplier is important. They can help you plan the timing of your delivery so the fresh concrete arrives when you’re ready to pour. Keep in mind that once concrete starts to set, you have limited time to work with it.

- Prepare the Job Site: Before the truck arrives, make sure the job site is ready. Clear any obstacles, check that the ground is level, and have tools on hand for the concrete pour. This reduces delays and avoids wasting the material.

- Plan for Placement: For larger or more complex jobs, consider whether you’ll need a concrete pump truck or other equipment to help with concrete placement. This is especially helpful for tall or spread-out projects.

Keeping Your Trucks in Top Shape

Concrete trucks take a beating. Over time, hardened concrete builds up inside the drum, reducing capacity and efficiency. This can mean fewer cubic yards per load and more downtime. Regular maintenance, like cleaning out buildup from the drum or repairing worn parts, is necessary to keep trucks working efficiently.

At Silo Pros, we specialize in maintaining and cleaning concrete mixer trucks, ready mix trucks, cement trucks, and more. Our concrete chipping services remove buildup, restoring your truck’s full capacity.