There are two structures commonly seen on farms across the United States; the silo and the grain bin. Both are storage structures dedicated to agriculture, but what exactly is the difference between them?

Silo vs. Grain Bin: What’s the Difference?

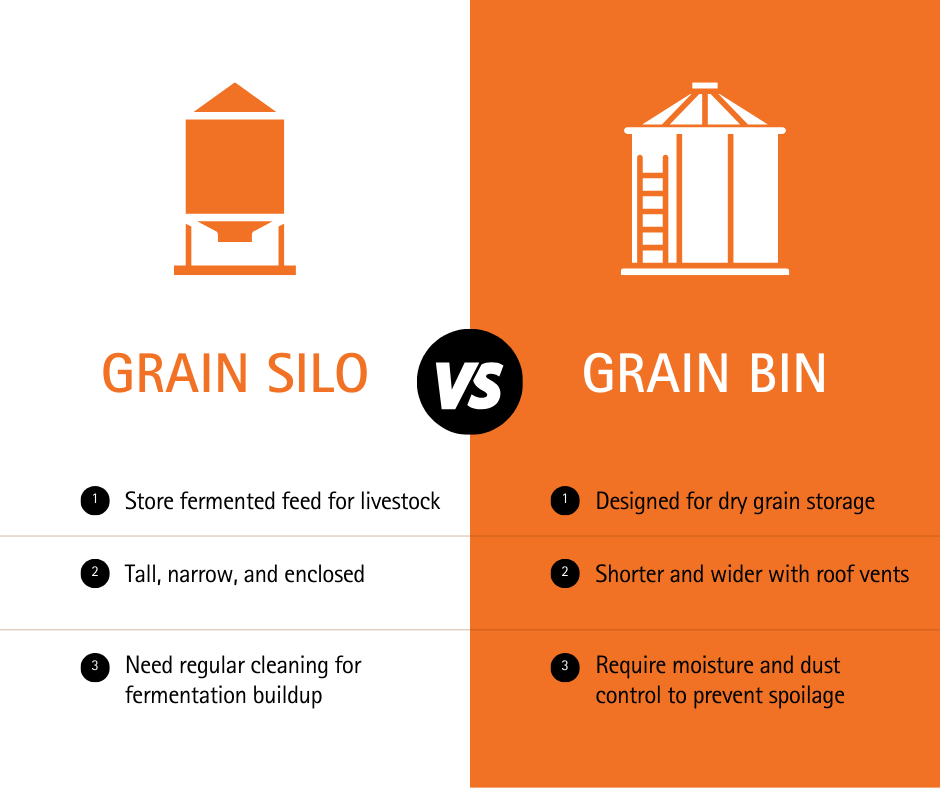

At first glance, grain silos and grain bins look very similar. They both stand tall on farmland or industrial sites and hold similar materials. But their uses vary a lot. Silos usually store fermenting materials like silage for dairy cattle and other livestock, while grain bins keep dry grains such as corn or soybeans dry and ready for transport.

A silo often has a cylindrical shape and can be made from concrete or metal. Silos can be tower silos (tall, narrow structures) or bunker silos (long, low spaces built into the ground). Grain bins, on the other hand, have peaked metal roofs with roof vents to manage moisture. These bins are typically built with corrugated metal and are mainly used to keep dry grain fresh until it’s sold or processed.

How They’re Built: Structure and Materials

Silos and grain bins aren’t built the same, and that’s because they serve different purposes.

Here’s a closer look at the structural differences between silos and grain bins:

- Silos: These tall, often cylindrical structures are typically made of concrete, metal, or a mix of both. You might find them on large farms or industrial sites where storage needs are high. They’re built to handle pressure from both the material inside and gases produced during the fermentation process. Silos often have an unloader chute that helps with getting the silage or other stored materials out smoothly.

- Grain Bins: Grain bins are shorter and wider than silos, with peaked roofs and roof vents that help prevent moisture buildup. Most are built with corrugated metal walls to give them extra strength. They’re designed to keep grains dry, as too much moisture can spoil the grain products stored inside. A bin wall is usually made to be strong enough to support the weight of dry grain while preventing grain dust and moisture issues.

How They’re Used: What Goes Inside Each?

What you put in a silo versus a grain bin depends on what you’re storing and why.

Let’s break it down to what goes inside and silo and what goes inside a storage bin:

- Silos: Farm silos are often used to store materials that need some fermentation, like silage and animal feed for livestock. The fermentation process, which generates carbon dioxide, can break down the silage, creating nutrient-rich feed. Silos are built to handle these gases and to ensure the contents stay at the right moisture level without spoiling.

- Grain Bins: Grain bins are designed for dry grain storage – like corn, soybeans, and other grains grown at large farming facilities. Farmers often use grain bins to keep their harvested grain fresh and dry before it’s sold or processed. Keeping these materials dry is critical to prevent spoilage, which is why grain bins are built with ventilation systems and peaked roofs that allow air to circulate properly. Grain handling in bins is typically straightforward, making it easy for farmers to store and access the grain.

Safety Concerns: Why Proper Maintenance for Silos and Bins Matters

One of the biggest concerns with silos and grain bins is safety. Each has its own set of risks, and regular maintenance is key to avoiding these.

- Silo Hazards: Silos contain gases from the fermentation process, like carbon dioxide, which can be dangerous if they build up. Entering a silo can be hazardous due to confined spaces, and proper ventilation is necessary to prevent accidents. Silos can also be vulnerable to pressure buildup, making routine inspections essential to keep them functioning safely.

- Grain Bin Hazards: Grain bins carry risks of grain entrapment and explosion hazards due to grain dust. Grain dust, when combined with an ignition source, can cause serious explosions, which is a huge safety risk on farms. Proper ventilation and regular cleaning can help minimize these risks. Grain bins are also prone to serious injury incidents if maintenance is neglected, as grain can flow unexpectedly and trap workers inside.

How Can Silo Pros Help Your Operations?

As we’ve uncovered, both structures come with their unique sets of maintenance needs and potential hazards. That’s where Silo Pros comes in, offering expertise and specialized services to maximize the efficiency and safety of your storage structures.

Silo Pros has been in the silo and grain bin maintenance industry for over 30 years, providing services that make a real difference.

- Comprehensive Cleaning: Whether it’s a silo or a grain bin, our vacuum truck services can remove grain dust, debris, and leftover material. This is especially helpful in reducing explosion risks and maintaining optimal storage space.

- Concrete Chipping and Maintenance: For silos, concrete chipping is essential to remove hardened buildup, ensuring that your storage space is maximized and materials can flow freely.

- Baghouse Maintenance: Proper filtration in baghouses and dust collectors is crucial for maintaining safe air quality and complying with environmental regulations. We inspect and repair these units so that your storage systems are always in line with safety standards.

One key factor that sets us apart is our adherence to safety standards, ensuring that both our team and your employees are safe during all maintenance operations. All our team members hold certifications in OSHA, MSHA, Confined Space, and Working at Heights, making us a safe and reliable partner.

With our range of services and commitment to safety, Silo Pros can help restore your storage facility’s efficiency, reduce operational downtime, and contribute to a safer working environment.

Maintaining Silos and Grain Bins Doesn’t Have to be a Daunting Task

Reach out to Silo Pros today, and let us help turn your farming operation into a more productive and safer place.