When it comes to mixing cement, not all mixers are built the same. From high-powered industrial mixers to portable concrete drums, each type of mixer has unique features that make it operate in totally different ways.

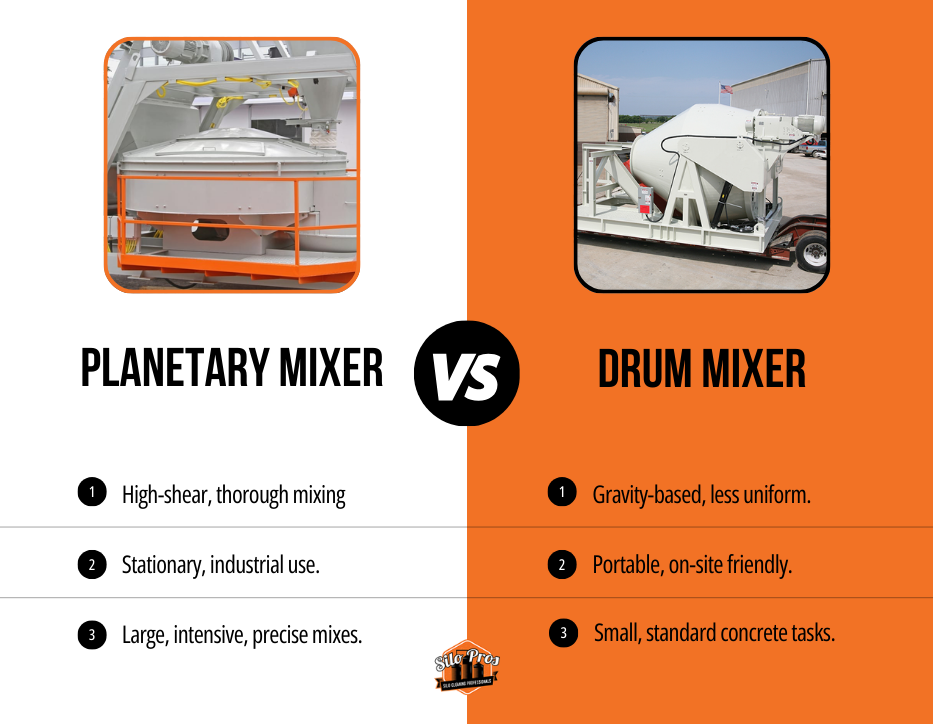

Two of the most common types of industrial mixers are planetary mixers and drum mixers. While they may look similar, they are used for very distinct purposes. Whether you’re working on a small construction site or a large industrial project, understanding the differences between these two types of mixers will help you appreciate how they’re designed to get the job done right.

What is a Planetary Mixer?

Planetary mixers, often referred to as planetary concrete mixers, are designed for high-shear, intensive mixing. They get their name from the planetary motion their mixing arms follow, moving in opposite directions to each other within the mixing vessel. This type of mixer is popular for creating an even and thorough mix, especially when dealing with concrete, refractory materials, and other industrial mixing needs.

The planetary mixer typically comes with a powerful motor and high-speed mixing capabilities. The mixing arms rotate around a central vertical shaft, allowing the mixer to reach all parts of the mixing vessel. This action makes it ideal for precast concrete and other materials that require a thorough mix. The high-shear mixer quality also ensures that all components are evenly distributed, which is essential when dealing with materials that need precision.

Features of Planetary Mixers:

- Mixing Motion: The planetary movement of the mixing arms ensures complete coverage of the mixing vessel, reducing the risk of unmixed portions.

- High-Shear Capability: These mixers are excellent for intensive mixing, especially fine particle distributions, providing a more uniform mix.

- Applications: Often used in industrial mixing, concrete mixer applications, refractory materials, and other demanding mixes.

- Versatility: Many planetary mixers can handle materials of different particle sizes and can work with both fine powders and coarse aggregates.

The vertical shaft design, coupled with the high-speed action, makes the planetary mixer a reliable option for large-liter input capacities. The discharge door on these mixers also helps speed up the release of the mixed materials, ensuring a short time output between batches, which is valuable for high-demand situations on construction sites.

What is a Drum Mixer?

In contrast, drum mixers rely on a simpler rotation system, where the entire drum spins to create the mix. Concrete drum mixers are familiar to anyone who has seen a typical construction site. The drum’s rotation is achieved either through electric power or, in many cases, a diesel engine for increased portability and power in the field. The design is relatively straightforward: the drum tilts and rotates, allowing gravity to pull the materials down through the mixture, which then re-cycles up the sides of the drum.

A drum mixer doesn’t offer the same high-shear mixing capabilities as a planetary mixer. Instead, it relies more on gravity to do the mixing. This type of industrial mixer is ideal for less demanding mixing tasks where a thorough mix is not as critical or where the mix contains fewer types of materials with similar particle sizes.

Features of Drum Mixers:

- Simple Mixing Action: The drum rotates continuously, allowing gravity to move materials, creating a continuous mixing process.

- Efficiency: Drum mixers work well for smaller mixers and portable applications, ideal for standard concrete mixing.

- Portable Power: Many drum mixers use diesel engines which makes them useful in remote areas where electricity isn’t readily available.

- Applications: Best suited for standard concrete mixing and other materials that don’t require intensive mixing action or precision.

Drum mixers are more common on smaller job sites, where large batches of concrete aren’t necessary. They are also highly mobile, with smaller mixers often mounted on trucks or trailers. Their efficiency makes them a go-to choice for general-purpose concrete mixing tasks on the go.

Key Differences Between Planetary and Drum Mixers

Mixing Technology and Thoroughness

- Planetary Mixers: With their high-shear mixer action, planetary mixers are highly effective in achieving a thorough mix, even with fine materials or those with different particle sizes. The mixing arms rotate in opposite directions, creating an even mix throughout the entire vessel.

- Drum Mixers: Drum mixers rely on the rotating drum’s natural pull, which is efficient for standard concrete drum mixer tasks but may not mix as thoroughly. Gravity does the work, so it may not be as uniform, especially for intricate mixes.

Design and Mobility

- Planetary Mixers: These are generally stationary mixers, designed for large industrial or precast concrete facilities where high capacity is a must. They are built for durability and precision but are a lot less portable.

- Drum Mixers: Known for their simplicity, drum mixers are highly portable, often powered by diesel engines for use in areas without electricity. They are perfect for on-the-go construction site mixing.

Capacity and Applications

- Planetary Mixers: Ideal for high-speed, high-shear, large-capacity mixing. They excel in creating intensive mixes and are suitable for industrial mixers or specialized concrete applications.

- Drum Mixers: More suited for smaller mixers and simpler applications, particularly when a thorough mix isn’t essential. These are frequently used in construction sites for general concrete needs.

Maintenance and Cleaning

- Planetary Mixers: With complex internal parts, planetary mixers require more meticulous cleaning and regular maintenance. Residual concrete can stick to the various parts, so thorough cleaning after each use is essential to avoid buildup, which could lead to performance issues.

- Drum Mixers: Drum mixers are generally easier to clean and maintain. The drum’s smooth, continuous surface allows for faster cleanup, especially if the concrete hasn’t set. However, regular checks for wear and tear on the drum’s surface and seals are still necessary to keep it in top shape.

Maximize Mixer Performance with Silo Pros’ Cleaning Services

Let our team handle the tough job of chipping away the concrete buildup from mixers and drums, ensuring your equipment stays efficient and ready for the next job.

Which Mixer is Right for Your Project?

When selecting the right concrete mixer, it’s important to consider the type of job, the volume of concrete needed, and the required precision.

Choosing between a planetary mixer and a drum mixer depends on your needs. If you’re working on projects that require precision, a planetary mixer is your best bet. It ensures that your materials are mixed to perfection, every time.

On the other hand, if you need to mix large batches quickly and without too much fuss, a drum mixer will get the job done. It’s especially useful for construction sites or when working with raw materials that don’t need a lot of precision, but speed is a factor.

Types of Concrete Mixers: Expanding the Range

Beyond planetary and drum mixers, the industrial mixing field includes a variety of other types of mixers:

- Twin Shaft Mixer: Known for its efficiency in mixing large quantities quickly, featuring two horizontal shafts that rotate in opposite directions.

- Ribbon Mixer: A horizontal ribbon mixer type, commonly used for powdered materials, but less suitable for concrete. These mixers are great for materials that need gentle but thorough blending.

- Pan Mixer: Another alternative, similar to the planetary mixer but without the high-shear capability. These mixers are user-friendly and easy to clean, making them popular for construction teams working on smaller sites.

- Cube Mixer, Static Mixer, Paddle Mixer: Used in various applications, each with unique mixing capabilities, but not typically for concrete.

Keep Your Mixers Running Smoothly with Silo Pros

At Silo Pros, we know that even the best mixers need regular care. Concrete buildup can slow down operations, reduce mix quality, and lead to costly repairs. Our team specializes in concrete chipping and cleaning services for mixers and drums. We remove hardened concrete, ensuring your equipment runs like new.

No matter what mixer you use, Silo Pros has the expertise to keep your mixers, drums, and silos running and your business moving forward.

Don’t Let Concrete Buildup Hold You Back

Silo Pros specializes in keeping your equipment in top shape with cleaning, inspection, and maintenance services.