The term “silo” refers to a structure used to store bulk materials. While most people think of silos as large, towering structures on farms, they actually come in many forms and serve a wide range of industries beyond agriculture. From storing grains like dry corn to managing livestock feed, silos help maintain the quality of stored products while preventing spoilage.

Different Types of Silos

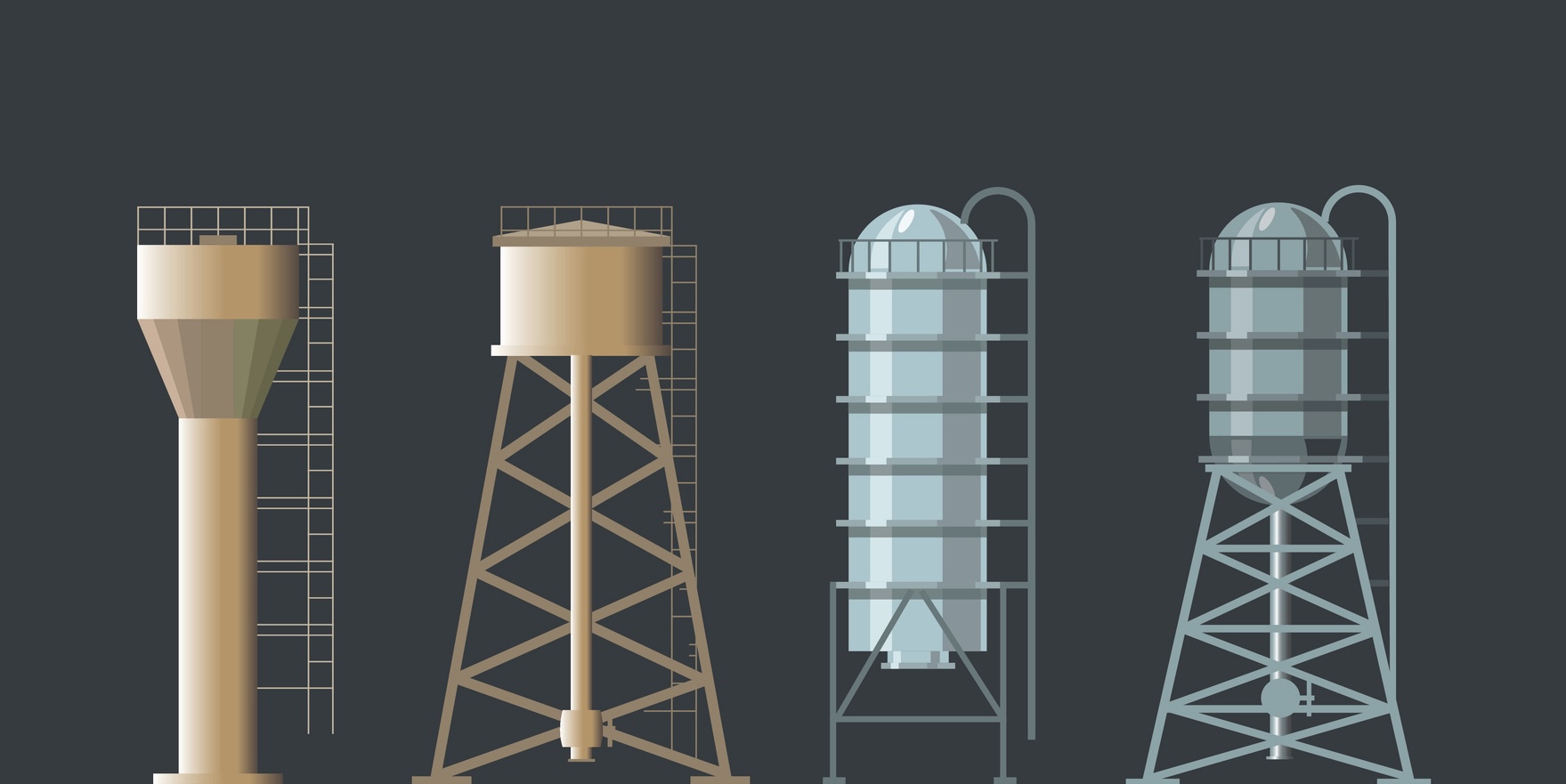

Understanding the different types of silos is important for anyone working in farming or industrial settings. Here’s a look at the most common types:

1. Tower Silos

Tower silos are probably the most iconic type of silo, easily recognizable as tall, cylindrical structures. They can be made from concrete, concrete staves, or even stainless steel. Round tower silos are often used for storing grain, silage, and other bulk materials. These silos are built vertically, making them ideal for storing large quantities of material in a compact footprint. The concrete walls of these silos provide durability and stability, making them suitable for long-term use.

- Use: Ideal for storing silage, grain, and other agricultural products.

- Common Materials: Concrete staves, stainless steel, concrete walls.

- Examples: Many older farms in the United States feature concrete stave silos, while newer installations may use stainless steel for better resistance to the elements.

2. Bunker Silos

Bunker silos are horizontal structures, usually constructed with concrete walls, where silage is packed tightly to ferment. This type of silo is perfect for large-scale livestock operations, as it allows farmers to store large quantities of feed. The silage pile is often covered with plastic sheets to prevent oxygen exposure, making it a low-oxygen silo.

- Use: Primarily for storing silage and other livestock feed.

- Common Materials: Concrete walls, plastic sheeting.

- Advantages: Easy access with an unloading mechanism like a tractor or front-end loader.

3. Grain Bins

While often confused with grain silos, grain bins are technically different. They are typically shorter and wider than tower silos, designed specifically for dry grain storage like corn, wheat, or soybeans. Grain bins often feature an unloading mechanism at the base for easy removal of stored grain.

- Use: Store grain, especially corn and soybeans.

- Material: Metal construction, usually corrugated steel.

- Notable Sites: Some repurposed grain bins, like those seen at Magnolia Market by Joanna Gaines, have become trendy venues for events like food truck parks.

4. Bag Silos

Bag silos are large, plastic tubes filled with grain or silage. Unlike permanent storage silos, bag silos are portable and can be placed wherever space allows. They are particularly useful during bumper crop years when extra storage is needed. They are filled and sealed on the farm and can be an economical option for smaller operations. The bag’s tight seal also aids in the fermentation process for silage.

- Use: Storing grain, silage, or other food products temporarily.

- Advantages: Flexibility and ease of setup.

- Common Users: Small farms and operations that need a temporary solution.

5. Concrete Silos

Concrete silos, including those made of concrete staves, are known for their durability. These silos can be built as tower silos or bunker silos, offering versatility depending on the user’s needs. They are widely used for storing grains, silage, and even bulk materials like wood chips.

- Use: Storing bulk materials, grain, and silage.

- Material: Concrete staves, concrete walls.

- Durability: Can withstand harsh weather conditions, making them a long-term solution.

6. Metal Silos

Metal silos, usually made of stainless steel or other durable metals, are another popular choice. They are ideal for storing food products or bulk materials that require a clean and secure environment. The use of stainless steel offers excellent resistance to rust and corrosion, making these silos suitable for various climates.

- Use: Storing grain, wood chips, and other bulk materials.

- Material: Stainless steel.

- Examples: Often seen in modern farming facilities and industrial sites.

7. Low Oxygen Silos

Low-oxygen silos are specialized for the fermentation process, particularly for silage. These silos create an airtight environment that prevents oxygen from spoiling the stored materials. The lack of oxygen ensures that the silage ferments properly, preserving the nutritional value of the livestock feed.

- Use: Storing silage to maintain high nutritional value.

- Common Materials: Concrete or metal.

- Ideal For: Livestock operations that need high-quality feed.

8. Missile Silos

A unique use of silo structures is the missile silo, used by the military to store and launch missiles. These silos are typically underground and heavily fortified. While not used for agricultural purposes, they represent an interesting application of the silo concept.

- Use: Military storage for missiles.

- Material: Reinforced concrete.

- Location: Mostly found in strategic military locations across the United States.

Repurposing Old Silos

Old silos, especially farm silos, can be repurposed for various uses. For example, some people turn concrete silos into observation towers or convert grain bins into living spaces. Popular sites like Magnolia Market have embraced the trend of turning old silos into attractions, blending history with modern customer experiences.

The Importance of Silo Upkeep

No matter what type of silo you use—whether it’s a tower silo, bunker silo, or a grain bin—regular inspections and maintenance are crucial for ensuring long-term performance and safety. Silo structures, especially those with concrete staves or metal construction, face challenges like structural wear, rust, or cracks over time. Without proper care, small issues can escalate into costly repairs or even compromise the integrity of your storage silos.

For industries that rely on bulk material storage, keeping silos in good condition is a must.

Trust the Pros for Your Silo Maintenance

At Silo Pros, we specialize in keeping your silos in top condition through expert inspections, maintenance, and repairs. Whether you need a thorough inspection of your grain silo, maintenance for your concrete stave silos, or repairs to ensure your bulk material storage remains secure, our team has the experience to get the job done right.

Don’t Let Minor Issues Become Major Setbacks

Reach out to Silo Pros today and ensure your silos continue to operate at their best.