The Short Answer: Preventing combustible dust incidents requires a combination of proper housekeeping, maintenance, and safety protocols. Regular cleaning, dust collectors, and ignition source control form the foundation of an effective dust hazard management program.

Grain dust explosions rank among the most devastating accidents in industrial facilities, with even small amounts of airborne dust particles creating potentially explosive conditions. These combustible dust explosions have resulted in millions of dollars in damage, serious injuries, and tragic loss of life across grain elevator operations of all sizes. The concentration of fine particles during handling and storage creates ongoing potential hazards, as combustible dust can quickly accumulate in confined spaces like silos and handling equipment.

The good news is that dust-related disasters are preventable through practical safety measures. This guide walks through the proven preventive measures to control combustible dust hazards, maintain clean facilities, and protect both workers and valuable agricultural products. By implementing the right combination of proper housekeeping practices, engineering controls, and workplace safety protocols, you can significantly reduce the risk of dust explosions at your facility.

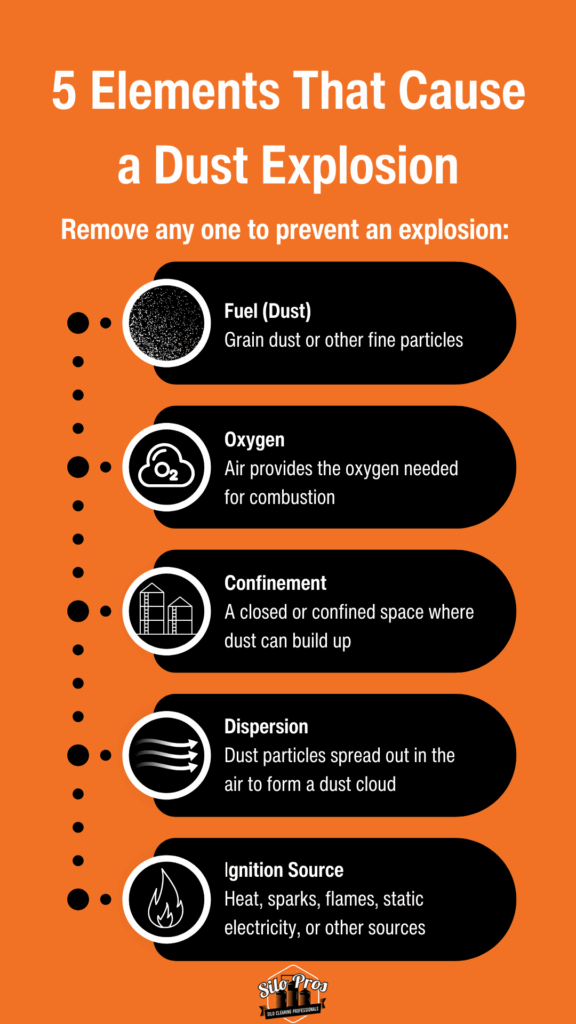

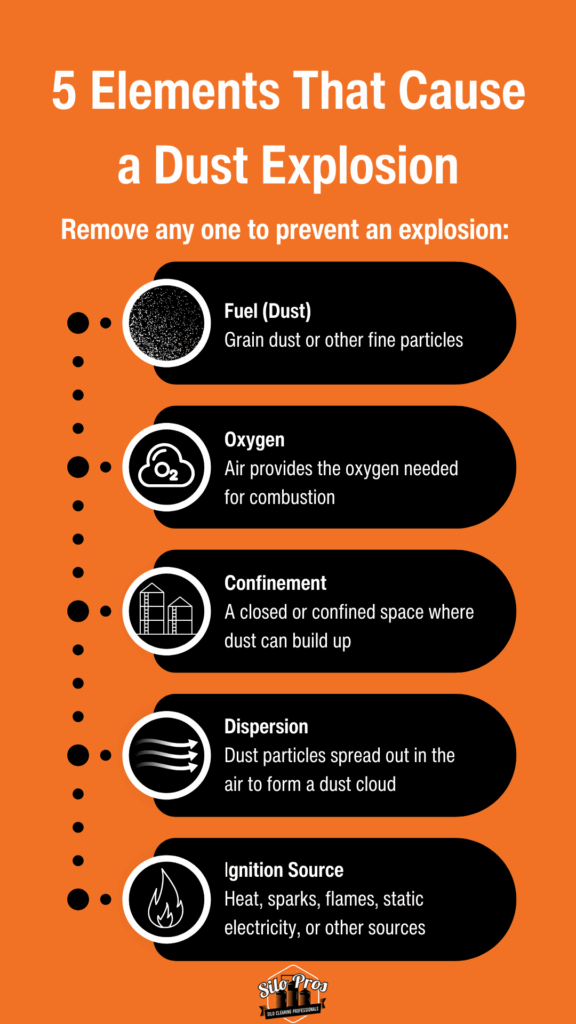

A dust explosion needs five things, known as the dust explosion pentagon: fuel (dust), oxygen, confinement, dispersion, and an ignition source. When grain dust hits its Minimum Explosible Concentration (MEC), usually about 50 g/m³, the risk of ignition becomes very high.

Common danger zones include:

A dust explosion needs five things, known as the dust explosion pentagon: fuel (dust), oxygen, confinement, dispersion, and an ignition source. When grain dust hits its Minimum Explosible Concentration (MEC), usually about 50 g/m³, the risk of ignition becomes very high.

Common danger zones include:

Understanding Combustible Dust Hazards in Grain Storage

Grain dust is made up of tiny dust particles from grains, oilseeds, and other crops that break off during handling and storage. This includes broken kernels, grain hulls, and bits of agricultural products that get into the air during operations. The smallest particles, less than 420 microns, are the biggest potential hazard because they stay floating in the air and spread through the entire industrial facility. Dust clouds form during common tasks. Loading and unloading grain creates combustible dust clouds as the grain moves through transfer points. Belt conveyors, bucket elevators, and grain legs also create combustible dust through mechanical movement. Even grain settling in bins makes fine dust that sticks to surfaces and electrical equipment. A dust explosion needs five things, known as the dust explosion pentagon: fuel (dust), oxygen, confinement, dispersion, and an ignition source. When grain dust hits its Minimum Explosible Concentration (MEC), usually about 50 g/m³, the risk of ignition becomes very high.

Common danger zones include:

A dust explosion needs five things, known as the dust explosion pentagon: fuel (dust), oxygen, confinement, dispersion, and an ignition source. When grain dust hits its Minimum Explosible Concentration (MEC), usually about 50 g/m³, the risk of ignition becomes very high.

Common danger zones include:

- Bucket elevator heads and boots

- Enclosed conveyor galleries

- Storage bin headspace

- Dust collectors systems

- Grain receiving areas

- Enclosed processing equipment

Dust Control and Housekeeping Practices

Written Program Structure

Regular cleaning schedules must cover primary dust-producing areas like grain receiving pits, storage bins, and loading zones. The program should map out daily, weekly, and monthly tasks to prevent dust explosion risks. Assign specific staff members to each cleaning zone and task. Include detailed procedures for recording completed work and tracking problem areas.Safe Cleaning Methods

Use approved dust collectors with appropriate filters for combustible dust removal. Prefer vacuum cleaning for dust removal, and use compressed air only if allowed by regulation and paired with effective dust collection to prevent creating airborne dust clouds. Clean spills immediately using proper tools and techniques. Work from top to bottom in confined spaces, removing dust particles from overhead areas first.Engineering Controls

Install ventilation systems at transfer points where grain moves between equipment. Position exhaust hoods to capture grain dust at its source. Modern cyclone collectors and baghouse filters effectively remove airborne dust particles. Properly sized dust collection systems maintain negative pressure in dusty areas.Dust Reduction Techniques

Apply food-grade mineral oil or other approved dust suppressants during grain handling to reduce potential hazards. Install enclosed conveying systems and sealed transfer points. Use dust-tight connections between equipment. Consider pelletizing materials when possible to minimize combustible dust generation.Monitoring and Maintenance

Document daily workplace safety activities in logbooks. Inspect dust collection systems weekly for proper operation. Schedule regular filter changes and equipment maintenance. Track dust levels in different facility areas to identify problem spots needing extra attention. Regular equipment inspections help catch wear and tear that could lead to increased dust production.Equipment Monitoring and Maintenance

Regular monitoring of mechanical and electrical equipment prevents potential ignition sources that could ignite combustible dust in grain elevators. Bearing sensors track temperature changes in equipment, alerting maintenance teams before dangerous overheating occurs. Maintenance staff should check bearings during daily walkthroughs and record temperature readings in equipment logs. The maintenance team should follow a detailed schedule for equipment inspections, lubrication, and parts replacement. This preventive measure stops mechanical failures that could lead to heat or spark generation.Static Electricity Control

Static electricity builds up as grain dust moves through handling systems. Installing proper grounding and bonding systems throughout the industrial facility reduces this risk. All conveying equipment needs solid electrical connections to ground, while workers should wear static-dissipative footwear when working around dust explosion hazard areas.Hot Work Safety Procedures

Hot work permits must be obtained before any welding, cutting, or grinding takes place. These activities should happen away from grain dust explosion zones whenever possible. When hot work must occur near grain handling areas, maintain a fire watch for at least 60 minutes after hot work per NFPA 51B (or at least 30 minutes per OSHA minimum), and extend the monitoring period as needed for added safety..Electrical System Safety

Install dust-ignition-proof or dust-tight electrical equipment rated for Class II (Group G) locations in grain handling areas, as required by NFPA 70 (NEC). This includes motors, lighting, switches and control panels. Regular inspection of electrical systems helps identify worn wiring or connections that could create ignition sources.Foreign Material Detection

Magnetic separators and metal detectors remove ferrous materials that might create sparks in grain handling equipment. These systems need daily testing and cleaning to work properly.Employee Training

All employees need thorough training on occupational safety procedures. This includes proper equipment operation, cleaning methods, hot work rules, and emergency response. Training must be documented and repeated at least annually, as required by OSHA 29 CFR 1910.272(e)(1).Facility Design and Emergency Planning for Dust Explosion Prevention

Proper facility design combined with well-planned preventive measures forms the foundation of combustible dust incident prevention in grain elevator operations. Modern industrial facilities incorporate multiple layers of protective systems to minimize explosion risks and ensure workplace safety.Explosion Protection Systems

Dust explosion protection begins with deflagration venting (e.g., explosion vent panels) and isolation devices, designed and installed per NFPA 68 and NFPA 69 to safely relieve pressure and prevent propagation. These panels direct potential combustible dust explosions upward and away from work areas and electrical equipment. Spark detection systems installed throughout the facility automatically trigger suppression mechanisms when they detect potential ignition sources.Venting and Pressure Relief

Every confined space handling grain requires specific ventilation system calculations based on volume and material flow. Pressure relief vents, installed on silos and processing areas, open automatically when pressure builds beyond safe levels. These vents must face away from buildings, walkways, and other work zones.Bucket Elevator Safety

Bucket elevators need specialized monitoring systems, including:- Belt alignment sensors to detect mis-tracking and prevent friction heat

- Speed monitoring devices

- Bearing temperature sensors

- Anti-static belting materials

Emergency Response Protocol

The facility’s safety protocols must outline clear procedures for different scenarios. This includes:- Specific alarm signals for different types of dust hazards

- Mapped evacuation routes with alternatives

- Designated meeting points outside the facility

- Emergency coordinator assignments for each shift