The Short Answer: Vacuum trucks (also called vac trucks) are specialized vehicles equipped with powerful vacuum systems that can remove and transport dry materials, liquids, and sludge. These industrial vacuum trucks are valuable tools for farmers and silo operators who need efficient cleaning and material handling solutions.

For farmers and agricultural operators, vac trucks are game-changers in maintaining clean, safe, and productive storage facilities. These heavy-duty applications use strong vacuum power to clean out silos, remove grain debris, and handle various materials that regular equipment just can’t manage. They’re particularly useful for clearing out tough-to-reach spots in tall silos and handling both wet and dry agricultural materials.

In this guide, you’ll learn everything you need to know about vacuum truck services – from how they work to the different types available. We’ll cover their main uses in agriculture, what makes them different from standard cleaning equipment, and how to pick the right one for your farm operations. Whether you’re considering getting a vac truck service or just want to understand these machines better, we’ve got you covered with practical, straight-to-the-point information that will help you make smart decisions for your agricultural operation.

How Vacuum Trucks Work

Basic Components

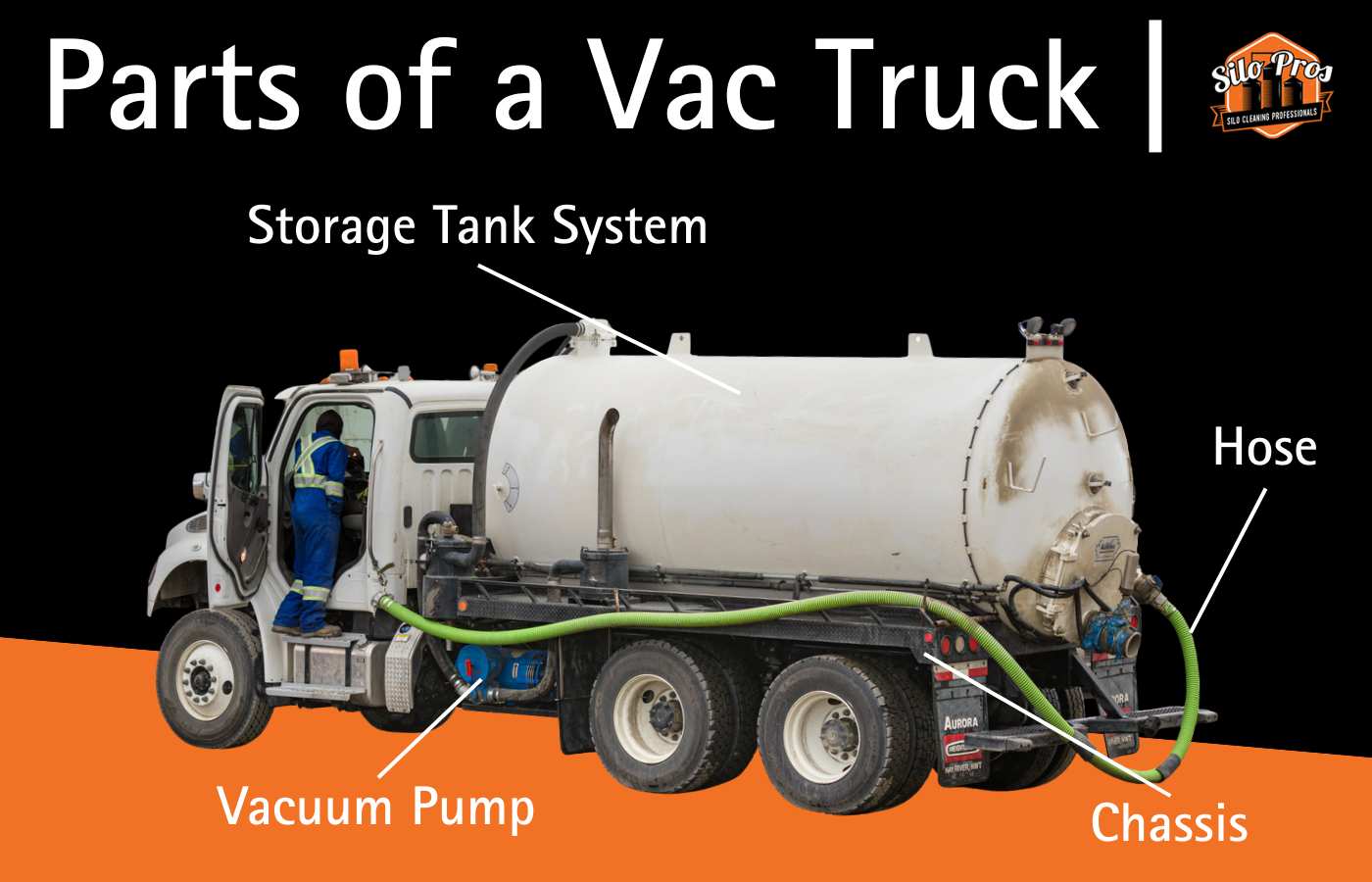

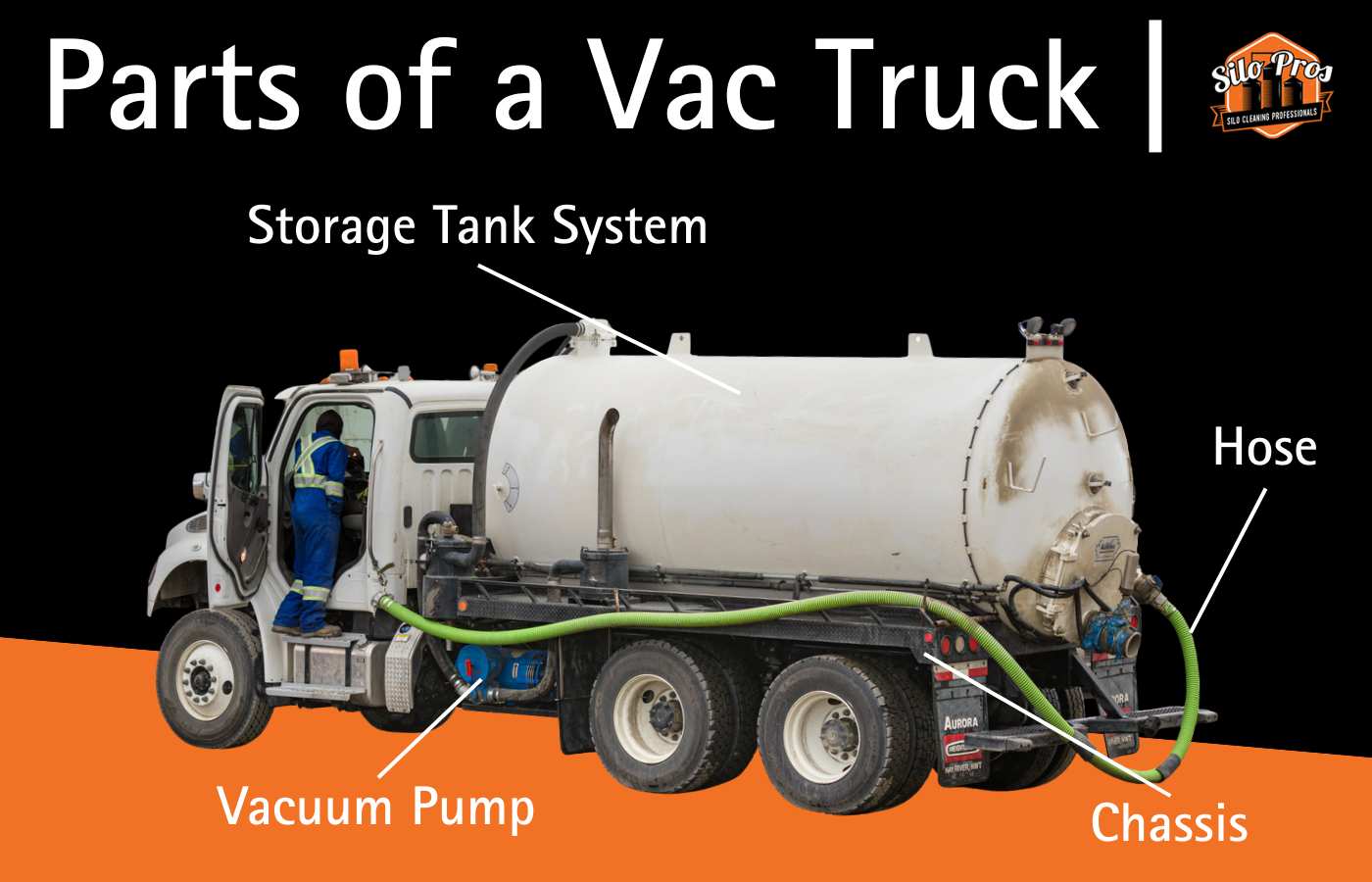

Storage Tank System: The heart of a vac truck is its storage tank system, which includes a heavy-duty cylindrical tank mounted on an industrial truck. These tanks are built with high-quality materials and special coatings to handle different types of waste. Chassis:The chassis on a vac truck (vacuum truck) is the base framework that supports the entire vehicle, including the engine, cab, wheels, and drivetrain. It serves as the foundation onto which the vacuum system and other components are mounted. The chassis determines the truck’s load capacity, power, and mobility, making it a critical part of the vac truck’s performance and suitability for different job types. Vacuum Pumps: The vacuum pumps sit between the tank and truck engine, converting engine power into suction force. Common types include rotary vane and liquid ring pumps, each suited for different materials and job conditions. The efficiency and strength of the vacuum pump directly impact the truck’s performance on-site. Hose: High-quality hoses connect to the tank through a system of primary and secondary shutoff valves that control material flow. Made from durable, flexible materials like rubber or reinforced plastic, the hose is designed to handle a wide range of substances, including liquids, sludge, and solids.Operating Process

The vacuum pump creates a powerful vacuum by forcing air out of the tank, dropping the pressure inside. When operators open the suction valves, the pressure difference pulls in outside air along with any materials in front of the hose. The industrial vacuum is strong enough to lift up heavy materials like wet grain, sand, and thick liquids. The collected debris gets stored in the main tank until it’s full. When it’s time to empty, operators use the tank’s bottom valve or connect to a discharge hose to remove the contents.Safety Features

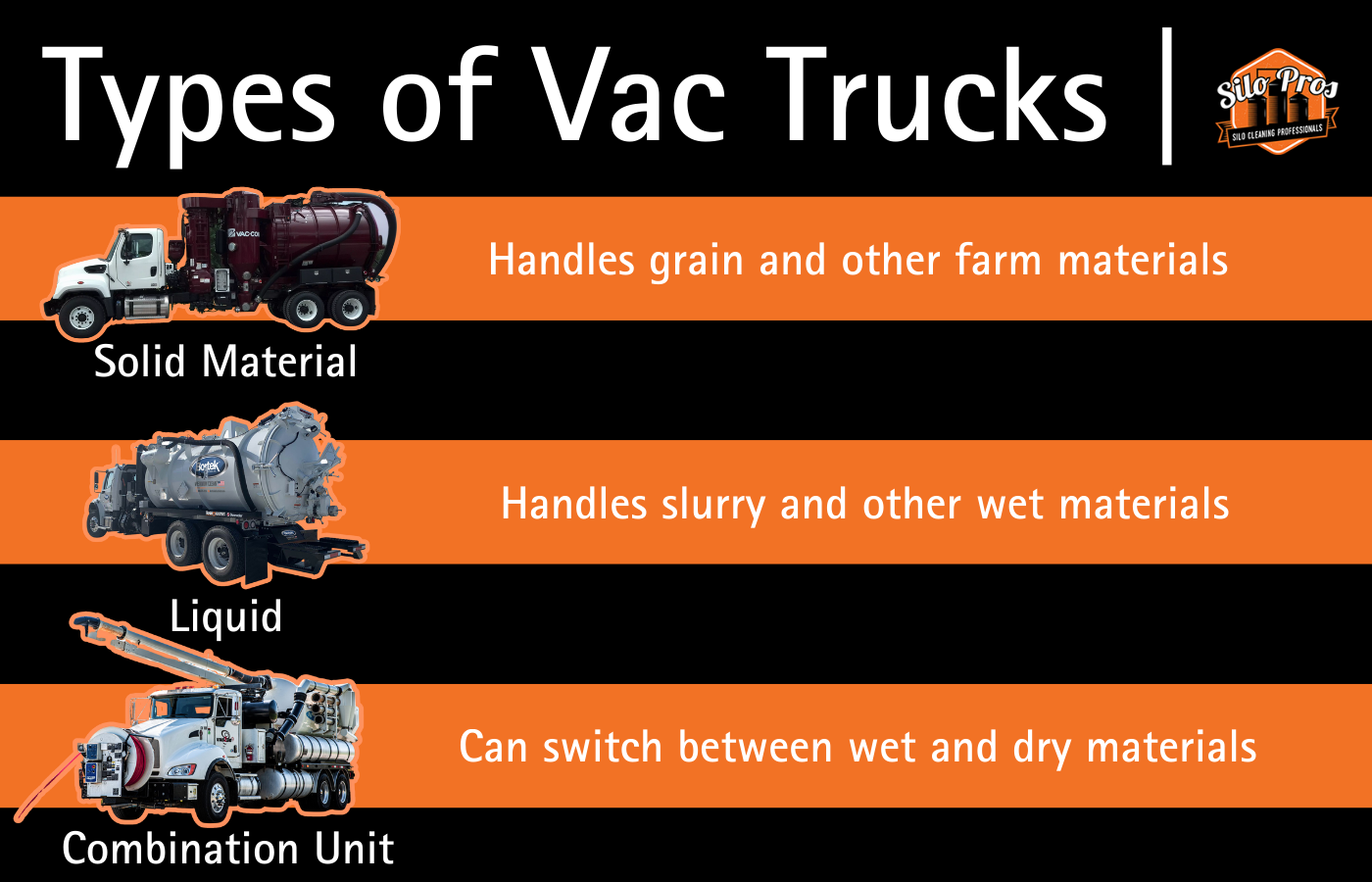

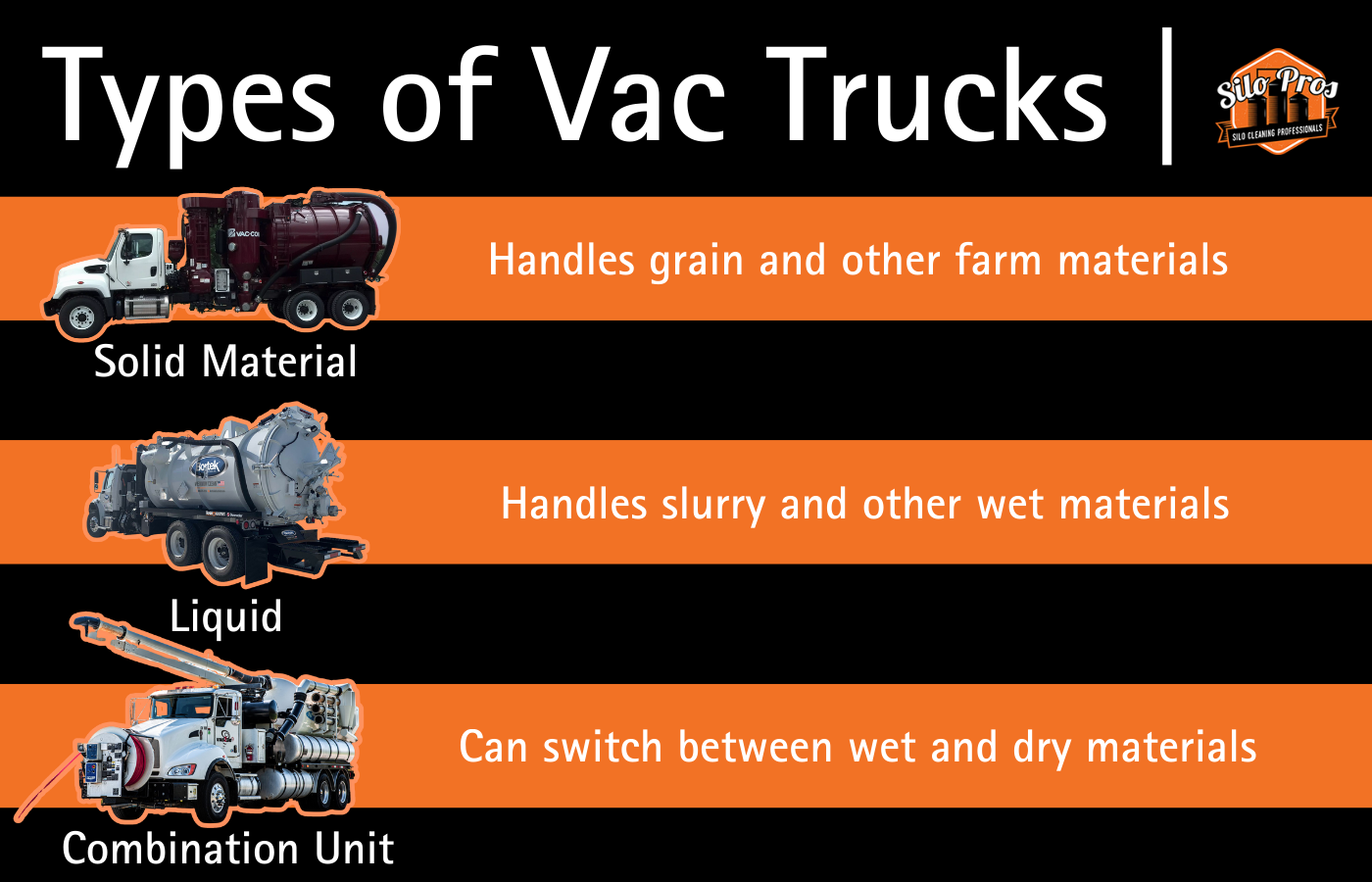

Vacuum trucks come loaded with safety systems to protect both operators and equipment. Automatic shutoff valves kick in when the tank reaches capacity to prevent overflow. High pressure relief valves make sure the vacuum pressure stays at safe levels and won’t damage the tank. The filtration system catches debris before it can reach and harm the vacuum pump. These filters also stop harmful particles from being released into the air during operation.Types of Vac Trucks for Agricultural Use